Sachet is a type of individual packaging of portioned products that is widely in demand in the food, pharmaceutical and cosmetic industries. Demand for these compact packaging in the consumer environment is growing rapidly every year. This trend is primarily associated with mobility and convenience of sachets, which are the main companions of the modern buyer. The appearance and distribution of these packages is dictated by the current concept of the everyday rhythm of life, when everything you need is at hand, does not burden large volumes and provides flexibility of use.

We offer you to check out in details what sachets are, what types of them exist and what their advantages are. In addition, we will talk about how the processes of packaging products in a sachet under production conditions take place, what resources and equipment are needed for this.

So what is a sachet and what is it made of?

Sachets are 3 or 4 seam bags of square or rectangular shape. The name "sachet" comes from the French word "sachet", which means "pouch". The ancestors of such packages were leather wineskins and fabric bags, which were used to fill with herbs and other loose masses. Such packages, of course, could not provide complete sealing and preservation of all product properties and in the process of finding the best solutions, their appearance was constantly changing. Currently, the most commonly used sachets are made of polymer multilayer films, but you can also find such packages made of combined materials (paper, foil, fabric, etc.).

What products are packaged in sachets?

Sachets are mainly used for packaging loose, powdery and liquid products, such as coffee, spices, sugar, vanillin, yeast, gelatin, sauces, dry confectionery mixtures, instant drinks, cosmetic creams, shampoos, shower gels, powder medicines for humans and animals, fertilizers, pest control products, wipes and other consumer goods. Sachets are also widely used to create trial samples of products that are convenient to offer for familiarization to consumers. Such mini-packages are especially in demand in a number of segments of the service sector: catering, tourism, hotel business, and transport services.

The advantages of mini-packages such as sachets are obvious:

· Mobility. Such bags can always be taken with you: they are compact and lightweight, which is very convenient for the end user.

· Tightness. Due to the high quality sealing of the seam, the absolute tightness of the bag is achieved, which eliminates the loss of the product and the change in its properties.

· Excellent strength characteristics of the materials from which the sachets are made, ensure the integrity of the package and its contents during transportation.

· Hygiene. A mini-bag is an individual, securely packed portion of the product that is used immediately after opening.

How is the product filling in sachets performed?

In production conditions, products are packaged in sachets using specialized equipment. It can be either separate installations that perform dosing, sealing, labeling and other operations in manual or semi-automatic mode, or multi-functional machines that implement all processes automatically, according to a given program. Monoblock installations can have horizontal or vertical execution. The first type is more suitable for packaging bulk and gel-like products, and the second type is more suitable for single articles (for example, napkins).

The choice of equipment for packaging in a sachet depends on a number of factors: the shape, material and dimensions of the bags, the type of product and other individual characteristics. The classic packaging technology in sachets includes the following steps:

1. Formation of packages from prepared material (most often a polymer film is used for this purpose).

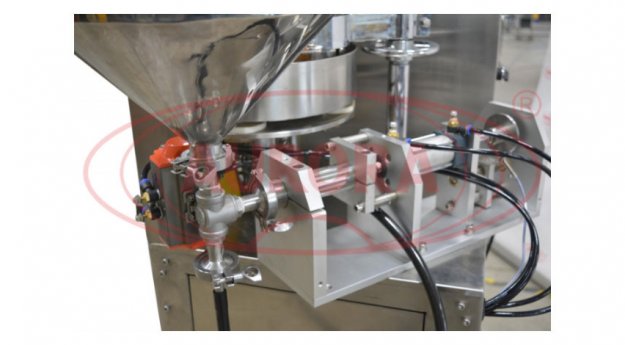

2. Dosing of the product. Depending on the type of product, packaging systems for sachets can be integrated with screw, volumetric and piece dispensers or flow meters.

3. Sealing packages. To seal the open side of the bag, a standard heat-welded seam, a reusable zip-lock fastener and an integrated valve with a screw cap can be selected.

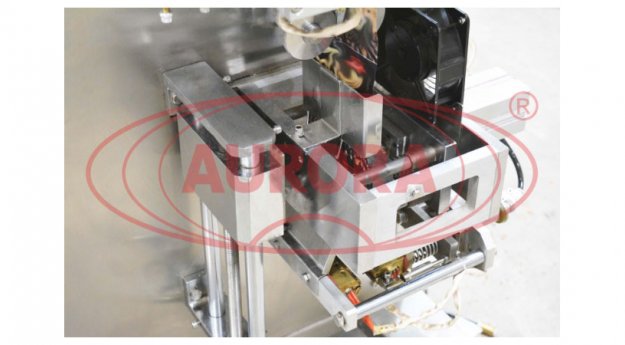

Installations can be equipped with additional units, for example, a section for packing sachets in secondary packaging (box, outer, show box, etc.). Let us have a detailed look at the principle of operation of these units using the example of automatic packaging machine “MASTER MZ-400ED, produced by our company. The monoblock is specially designed for packaging granulated coffee and condensed milk in double sachets with Euro Hang Tab. The installation has a compact floor design with a vertical arrangement of units.

At first, a reel with “Buflen” is mounted on the material supply roller. Next, the film is unwound to a predetermined length, which is controlled by optical sensors, after which a date is stamped on it. The next step is the alignment and positioning of the material through putting a control mark. After that, the film moves to the molding area, where it is folded and the shape of the future package is created. Then the bag is sealed on three sides, with perforation being performed on the middle seam to form two pockets. The finished sachet moves to the dosing unit. Filling bags with condensed milk is done by a piston type dispenser. Granulated coffee is supplied with a vibrating base. Next, the upper part of the package is sealed, after which notches are affixed using the built-in side knives to ensure easy opening of the package by the consumer. Then, a Euroslot is formed on the package, which is necessary for the convenience of placing goods on racks with hang tabs. The final step is to cut the bag and move it into the discharge tray.

The device is focused on working with large volumes of products and provides productivity up to 1200 bags per hour. Control is carried out from the PLC panel. To apply the date, a thermal transfer dater is used. The sealing device realizes the thermal effect only on the packaging material without risk of heating the product. The machine is a classic one in functionality and fabrication. The model has a number of modifications, including for packaging in triple sachets and packages of a non-standard type. The selection of materials for manufacturing is carried out based on the characteristics of the industry and the specifics of the customer’s production.

This and other equipment for packaging in sachets produced by our factory "AURORA PACK ENGINEERING", has proven itself on the production sites of various industries.Machines save packaging material, perform high-precision product packaging and hermetic sealing, which, combined with environmental friendliness and ease of maintenance, make them widely in demand in their segment.

If you have already decided on the choice of technology for packaging your product in sachets and select the necessary equipment, please contact us! Our experts will help you in finding the best solution!