Counteraction to the microbial environment is the most important component of a healthy lifestyle for a modern person. Every day we are faced with a mass of pathogenic microorganisms that must be destroyed in a timely manner, primarily from the hands, as the most contaminated parts of the body.

Peaks of seasonal diseases (influenza, acute respiratory viral infections) fall in the spring and autumn periods, and recently WHO declared the spreading around the world coronavirus a pandemic. In this regard, antiseptic drugs are becoming one of the most popular categories of household goods. In this article, we will share our own experience in production of equipment for preparation, filling and packaging of skin sanitizers, disinfectants, vaccines and other sterile pharmaceutical preparations.

What are skin antiseptics (sanitizers)?

Sanitizers are alcohol-based disinfectants, which may also include polyacrylic acid, glycerin, essential oils and a number of excipients. Today, antiseptic preparations in various forms are presented on the market: liquid, thick, powder, gel-like, pasty. Such products are available in vials, bottles, bags, tubes and other types of containers.

Compact and mobile skin sanitizers for hands in cartridges with dispensers are the most popular among consumers. This is due primarily to ease of use and ability to quickly process hands in any conditions. Preparations with alcohol content of more than 60% effectively destroy a wide range of bacteria, including acute respiratory viral infection and influenza viruses. A number of studies confirm that the regular use of these preparations in everyday life, offices, educational institutions and other public places allows reducing the incidence of viral infections by 20%.

What equipment is needed to pack sanitizers in consumer packaging?

Our company has extensive experience in production of equipment for filling and packaging skin sanitizers of various types and other drugs, including sterile ones. Most of the solutions were developed by our specialists from scratch, and are unique projects that have no analogues.

Regardless of which preparation is packaged and in what containers, packaging technology includes a number of mandatory steps:

· Product Dosing

· Capping / sealing

· Labeling and date printing on the package

In addition, stages of washing and sterilizing containers, mixing the product, purging with nitrogen, group packaging and others can be included in the general cycle of processes.

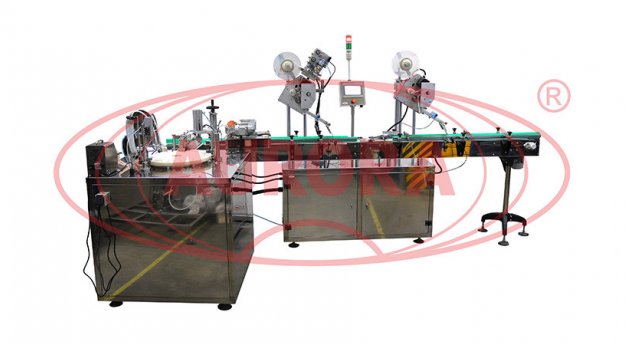

We produce both separate machines for autonomous execution of each operation, and complex installations, including fully automated ones. Thus, for filling and capping sanitizers in large-scale production facilities, we produce Monoblock “Master” with 8 piston dispensers, and “Master” MZ-400ED monoblock based on peristaltic metering pumps has been developed specifically for packaging alcohol-containing liquids. Filling Line “Master” NIAGARA for pharmaceuticals with a filtration system and ability to supply up to 3 liquid components is suitable for filling vaccines and other sterile preparations. These and other similar solutions are made of high quality materials and fully comply with the requirements of the international GMP standard.

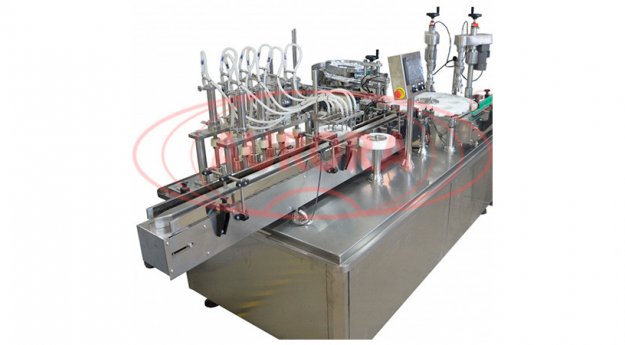

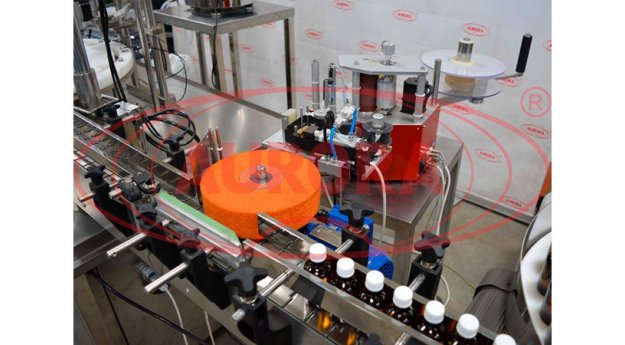

One of the latest successful orders fulfilled was our multifunctional “Cleanness” complex for filling, capping and labeling fifth-generation antiseptic sprays. The main requirement presented by the Customer to this complex was the optimal balance of functionality and compactness. We tried to take into account all the needs of the client and created a small-sized line consisting of a semi-automatic filling and capping monoblock and AE-5 labeling line with a container-flipping device. The unit performs a full cycle of filling a liquid preparation into plastic mini-cartridges. Let us dwell upon the features of the internal device, which contribute to the high efficiency of the machine.

The monoblock is equipped with a peristaltic metering pump with two nozzles, a cork inserter, a rotary table and a pneumatic cylinder. The advantage of the metering unit of the machine is the presence of a hydraulic compensator, which avoids excessive pulsation during bottling. Due to this, high dose accuracy and the absence of splashes when feeding the product are achieved. Due to the optical sensors of the presence of containers, the operation of all units is synchronized. The labeling line includes areas for positioning containers, applying labels on the front and back sides, flipping containers and smoothing labels with hold-down brushes.

The whole complex is controlled by a single operator panel equipped with a touch screen. The main working cycle is implemented automatically. Only setting containers to the filling position and the cork installation before capping are performed manually. Process coherence is achieved through an optical sensor system. If necessary, the installation can be upgraded to the individual characteristics of the production activities of a particular customer.

How can optimal conditions for filling sanitizers be organized?

Each company has its own characteristics, which suggest need for an original approach to equipment. Packaging of any medications, whether antiseptics, solutions, ointments, or any others, must be carried out in accordance with the GMP standards. According to the main provisions of this document, production equipment must provide for:

· No risk of product quality loss;

· Convenient working environment for the staff;

· Environmental safety;

· Easy cleaning and other care.

When packaging sanitizers, in addition to observing general requirements, a number of additional nuances must be taken into account. Thus, it is worth remembering that the high alcohol content in hand hygiene preparations makes them prone to inflammation. To eliminate the risk of fire, in some cases it is more expedient and safer to use explosion-proof equipment. In order to avoid evaporation of volatile alcohol-containing components, it is necessary to ensure a tight seal immediately after filling.

Our company "AURORA PAK ENGINEERING” experts elaborate on these and other issues related to the effective integration of produced machinery when processing requests from customers and manufacturers of antiseptics. Unconditional customer orientation helps us quickly find the best solutions. Currently, due to the trend towards the spread of coronavirus, the number of customers for equipment for the production and packaging of sanitizers has increased significantly. We quickly process incoming requests and, for our part, we do our best to assist our customers in producing quality products for consumers.