The conveyor is an integral part of any filling line and acts as a connecting link between different technological sections. By means of a conveyor, containers move from one unit to another, which ensures timely washing, dosing, capping, labeling and other operations. The difficulty in choosing the optimal conveyor lies in the fact that the installation must meet all the necessary technical requirements in a particular production line and fulfill the task effectively, stably and safely.

In this article, we will describe in detail how to choose a conveyor for individual production features. Our company has extensive experience in implementing projects to equip various bottling lines, and, in particular, their layout with conveyor systems. This has allowed identifying key criteria, the orientation on which will allow customers to quickly and correctly set the task for the supplier.

For a start, let us check what types of conveyors are on the market today. Conveyors of the following types are most often used to equip bottling lines:

-

Slat conveyors. In these systems, the load is moved through a deck of metal plates connected to the traction element. High strength characteristics allow the use of slat conveyors for working with glass and PET containers, cans, corrugated boxes, as well as containers that have a lot of weight (for example, 19 liter bottles of drinking water). Corrosion resistance of stainless steel allows you to easily move aggressive products. The main field of application is filling lines for cosmetics, pharmaceuticals, household and industrial chemicals (linear conveyor TL series, rotary slat conveyor TL series made of stainless steel).

-

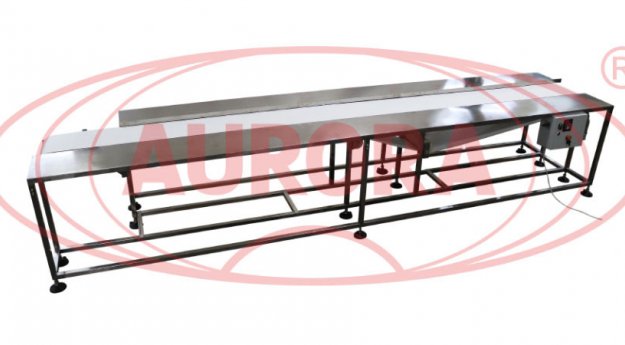

Belt conveyors. The main working body is a belt made of elastic material. Such conveyors are lighter than slat conveyors, and are most often used for moving soft and light loads (doy-packs, bags, packs, trays, plastic boxes, containers). Due to the high environmental friendliness of the installation, they are more in demand at enterprises producing food products, where they are used to transport meat, fish, vegetables, sweets and other finished products (two-meter belt conveyor, four-meter belt conveyor).

-

Roller conveyors. In these models, the working part consists of a group of rotating rollers. Installations can be used to move various non-bulk heavy loads, for example, cans, bottles, pallets, boxes (stainless steel roller conveyor of the TL series).

The choice of a particular type of conveyor, its performance and functionality depend on a number of factors.

Key criteria that determine the choice of conveyor for the line:

· Type of production

Any industry has its own characteristics, which are reflected in the production equipment. As for conveyor systems, according to this criterion they can be conditionally divided into three groups:

- For pharmaceutical or veterinary drug bottling lines. Here, the decisive factor will be the compliance of the conveyor system with the requirements of the international GMP standard.

- For food industry enterprises. The first priorities are absence of risk of contamination with the transported product and the negative impact of the conveyor on its taste.

- For non-food industries.

· Cargo features

On filling lines, the products can be moved both in their original form and packed. The most widely used consumer containers are bottles, vials, cans, bags, jars, boxes, pallets and other containers made of glass, plastic, metal, polymeric and other materials. Already at this stage, the supplier of conveyor equipment can determine the width of the future conveyor and the material of its manufacture.

· Line output

Depending on the required speed of cargo movement, the conveyor equipment is determined by the drive with the appropriate power and the optimal set of components. Each installation has its own limitations on maximum productivity, which must be taken into account when planning the subsequent capacity expansion.

· Line configuration

The conveyor of almost any type can have horizontal, vertical and inclined execution, the choice of which depends on the height of the connected equipment and other design features of the line. Depending on the number of threads, the installations can be single-row or multi-row.

The length of the route and the need for rotary sections are determined based on the individual layout of the entire complex.

· Usage Environment

When selecting a conveyor installation, it is necessary to take into account in which environment the equipment will be operated: indoors or outdoors. In addition, important factors are such as temperature range, humidity indicators and aggressiveness of the environment. In production with increased fire hazard and when working with flammable products, it is advisable to introduce explosion-proof conveyors.

· Type of automation

At the stage of the conveyor design, the manufacturer needs to know whether automation of its operation is necessary. Most models can be automated later, with further modifications, but this feature should be laid down initially. The production of control systems, push-button posts, operator panels, equipment with sensors and other additional devices is also individually made.

Clarification of the type of conveyor according to the above criteria will help you significantly narrow the search range of the desired installation. It remains to choose a supplier, and here we advise giving preference to well-known and well-established brands. Our company «AURORA PACK ENGINEERIING» manufactures and supplies reliable and high-quality conveyor equipment. Installations are developed as per both standard and individual projects. Within the shortest possible time, our specialists will select the most suitable conveyor system for your filling line. We offer flexible payment terms and a full range of services for the effective integration of installations in existing facilities (installation, installation supervision, commissioning and subsequent maintenance). Before being sent to the Customer’s site all conveyors pass a series of tests and are delivered with the necessary documentation.