Medicines are a particularly important type of pharmaceutical products, as they directly affect health and quality of life of the population. To create a truly effective and safe product, the manufacturer must pay attention not only to choice of raw materials and manufacturing technology, but to organization of technological processes as well.

The requirements for equipping pharmaceutical production are enshrined in special standards, the main of which is GMP. According to these regulations, equipment for the manufacture and packaging of drugs should fully ensure:

- compliance with the fixed technology,

- maintaining the structure and properties of the product,

- protection of the drug against the risk of pollution and contamination,

- convenience of management and control of work for personnel,

- ease of cleaning, other care and maintenance.

Focusing on GMP has already ceased to be a voluntary practice, today it is an indispensable component of the activities of any pharmaceutical company. In this regard, modern manufacturers are actively carrying out modernization and re-equipment of their sites, choosing more high-tech, powerful and reliable equipment to perform various processes. Compliance with the requirements of the standard applies not only to the direct manufacture of a pharmaceutical, but also to its packaging. We propose to consider in detail how the specificity of the drug affects the selection of suitable equipment for its fill and finish.

Types of equipment for bottling liquid, thick and powdered medicines

Medicines have various forms, i.e., states, in which it becomes possible to achieve one or another therapeutic effect. Based on this feature, these products are classified in medicine according to consistency, dividing into doses, spectrum of action and method of application. When choosing equipment for filling the drug, the consistency will become an especially important criterion.

What types of dispensers and other packaging systems are suitable for a particular type of drug and how do they differ?

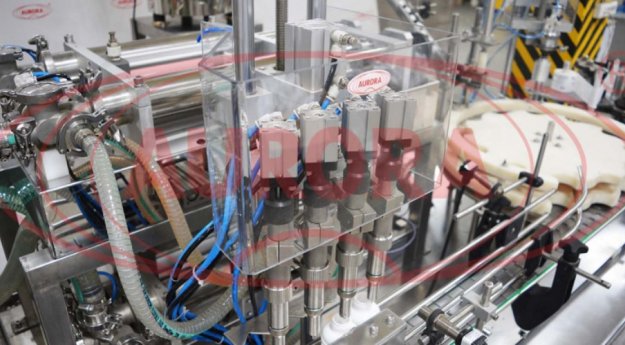

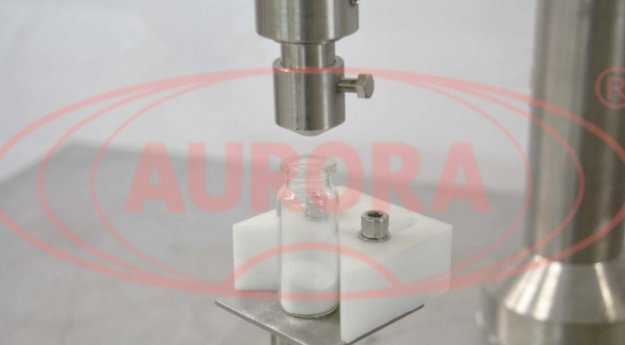

Liquid dosage forms

For dosed supply of liquid drugs (solutions, suspensions, emulsions, galenic preparations (tinctures and extracts), drops, syrups), peristaltic dosing pumps are most widely used. The units work by squeezing the hoses with a constantly rotating body (wedge pad, roller). The section with liquid is separated by a roller and, due to the occurrence of reduced pressure in another section, moves towards the outlet pipe. Liquid preparations are packed in jars, bottles and vials made of glass and plastic, ampoules, syringes and soft bags. Equipment for packaging medicinal liquids is on the market in a wide variety. There are separate models of dispensers, cappers and other machines, as well as complex units that perform the full cycle of drug packaging: filling lines (for example, “Master” filling line for infusion solutions, “Master” complex filling line for Bottle Pack) and monoblocks (monoblock filling and stoppering "Master" for penicillin vials MZ-400ED, monoblock "Master" for filling and capping pharmaceutical solutions, monoblock "Master" for filling drugs into glass vials with dropper and plastic screw cap).

Viscous pharmaceuticals

Thick and viscous pharmaceutical preparations, such as ointments, pastes, suppositories, gels and liniment, are packed using piston dosing units. The principle of operation of these machines is based on the movement of the piston, as a result of which vacuum appears under it, and the product is sucked from the receiving tank and fed into the container. During the reverse movement of the piston, the valve closes and the flow stops. Glass and plastic containers, as well as tubes are most often used for packing thick medicines. In addition to the classic dispensers, a large assortment of other packaging units for these pharmaceutical products is produced nowadays, including tube filling machines, linear and one-piece solutions (semi-automatic line for filling thick products "Master" MZ-400ED, monoblock "Master" with 8 piston dispensers, 5,000 vials/h for antiseptics, monoblock for filling and stoppering viscous products (gel for ultrasonography and hyaluronic acid) "Master" MZ-400ED).

Loose pharmaceuticals

For filling powdered preparations, characterized by flowability, screw dosers are used. The main working body of such machines is a screw (auger), which, rotating, moves the product into the packaging. When the auger stops working, the feed stops. Installations can be additionally equipped with agitators, which do not allow the product to stick together. For further packaging of powdered medicines, various models of blister machines, tablet presses and other units have been developed (MD-500T manual tablet press, BOOM-1 blister packaging machine, automatic monoblock for filling and capping bulk products MZ-400ED). In addition, there are special installations (capsulators), used for packing powders in gelatin or polymer capsules.

In recent years, there has been an increasing tendency among pharmaceutical manufacturers to switch to a flow mode of operation. Many enterprises, even producing products in small volumes, are keen to automate processes as much as possible in order to avoid any risks of releasing a poor-quality drug. Despite the high cost of arranging conveyor lines compared to manual and semi-automatic installations, this equipment allows you to achieve the highest accuracy of operations, significantly save time and, ultimately, pays off very quickly.